A PT Freeport Indonesia team fully experienced in navigating unexpected challenges once again has answered the call.

A delay in securing an export permit at the beginning of the year threatened to impede PTFI’s planned first-quarter shipments of copper and gold. Without that permit – required as a result of the shutdown of the new smelter facility damaged by an October 2024 fire – hundreds of thousands of tons of copper and gold-laden product would have no place to go.

A delay in securing an export permit at the beginning of the year threatened to impede PTFI’s planned first-quarter shipments of copper and gold. Without that permit – required as a result of the shutdown of the new smelter facility damaged by an October 2024 fire – hundreds of thousands of tons of copper and gold-laden product would have no place to go.

This is where the resourcefulness of PTFI’s Dewatering Plant team was critical, as it helped identify and utilize every possible place to store product until PTFI finally received its export permit in March.

“We’ve been through this several times going back to 2017, and each time Dewatering Plant employees have figured out how to store more product,” said Chris Zimmer, Executive Vice President over the port operations. The implications of the task were significant as hundreds of millions of dollars of copper concentrate with an average metal content of 26.5 percent copper and 18 grams per metric ton of gold were in play.

Storage space was at a premium, as the only product that could be loaded onto ships would be destined for the domestic PT Smelting facility in Gresik, East Java, where space was tight. The October fire at the company’s new smelter facility – also in Gresik – forced that smelter operation to shut down, and the company sought relief by applying for an export permit while repairs were being made to the facility.

Storage barns at capacity

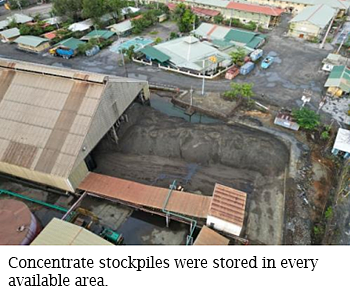

Not long into January, the three concentrate storage barns at the Dewatering Plant were overflowing with concentrate, and the material was stored in every possible nook and cranny around the barns, with an outdoor concrete pad quickly absorbing the rest. By the end of February, the team simply ran out of room at port site to store concentrate, and the mine and mill operations were forced to curtail production.

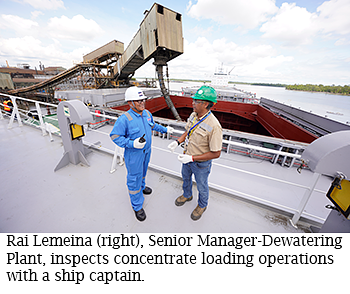

Jim Dellinger, Vice President-Operations Support, credited the team led by Rai Leimena, Senior Manager-Dewatering Plant, and Lucky Hermawan, Vice President-Marine Operations, with the resourcefulness to navigate the challenges exacerbated by the export permit delay.

“Rai and Lucky successfully coordinated multiple departments to creatively find more space to store the concentrate,” Dellinger said. In fact, the team has had some practice, as there had been other occasions where extra space was needed on short notice.

“We initially thought 180,000 (metric) tons was the limit, then 205,000, followed by 222,000 and eventually 225,000 at the peak,” Dellinger said. On this occasion, the area outside the barns was freed of excess materials and equipment. After maximizing the available space, the team found additional capacity on outdoor pads normally used for the filtrate from the filtration plant.

“We initially thought 180,000 (metric) tons was the limit, then 205,000, followed by 222,000 and eventually 225,000 at the peak,” Dellinger said. On this occasion, the area outside the barns was freed of excess materials and equipment. After maximizing the available space, the team found additional capacity on outdoor pads normally used for the filtrate from the filtration plant.

The stockpiles had to be compacted, involving equipment borrowed from other areas of the operation. However, over-compaction can result in plugging the conveyor chute system once loading would resume, so the process had to be carefully managed.

Additional space identified

More space also was found on the new shallow draft vessels the company recently placed into service to ship concentrate to PTFI’s domestic smelters. Three of those ships were used as floating storage.

“It was a carefully orchestrated operation,” said George Banini, Executive Vice President-Operations. Carl Tauran, PTFI’s Technical Mine Manager and Executive Vice President-Site Operations, said the can-do spirit of the PTFI workforce was evident from “the mines to the port and beyond.”

“Beyond” included teams in New Orleans and Spain who are responsible for marketing and shipping copper concentrate. PTFI finally received its export permit in mid-March. However, the international logistics team had been working throughout the delay to enable the team at Port Amamapare to quickly act on Day 1.

That involved the timing of a fine watch. Rhonda Schexnayder, Manager-Logistics, is a member of the team responsible for coordinating between the Port and the ship owners and brokers who would export the product.

“When we finally got the go-ahead, we had 13 vessels waiting, and it was time to roll. Normally, it takes from seven to 10 days to get a ship to Amamapare. In this case, they were already there,” Schexnayder said.

As negotiations between the ship owners and brokers, the customers hungry for product amid tight global supply and the port had been ongoing in anticipation of that go-ahead, Hermawan also had to practice diplomacy on the ground.

As negotiations between the ship owners and brokers, the customers hungry for product amid tight global supply and the port had been ongoing in anticipation of that go-ahead, Hermawan also had to practice diplomacy on the ground.

“We had to keep coordinating with the port captain, vessel masters and the loading crews,” Hermawan said. “So, we had to be in constant communication to get them to understand our loading targets and our unique operating environment with the constant cloudy weather.”

The new export permit allows PTFI to export 1.4 million wet metric tons of concentrate through mid-September. The permit was secured in mid-March, and by the end of the month, the team at the Port had shipped out more than 205,000 wet metric tons of concentrate for export.

The team is not slowing down. In April, it set a new all-time daily record, loading 25,000 wet metric tons of concentrate. Average daily loading is approximately 10,000 wet metric tons.

“There’s no time to pat ourselves on the back,” said Jim Guidry, Director-Marketing and Sales. “Our customers expect us to keep doing this. And we will.”