The ceremonial blast at a new underground mine production level is putting PT Freeport Indonesia on top of a rock-hard problem at what is expected to become one of the company’s top producing operations within a few years.

The first blast marks the beginning of mining at Production Block 4, an offshoot of an existing operation called the Deep Mill Level Zone (DMLZ) Mine. Seismicity challenges related to the nature of the rock being encountered in the DMLZ surfaced in late 2015. After implementing several mitigating strategies, the decision was made several years ago to reconfigure the mine.

The solution was to establish a new production level about 200 meters – or 650 feet – above the existing DMLZ and slightly offset it. That way, the problematic harder to cave, lower grade rock that had hindered progress is bypassed. Production of easier to cave, higher grade ore is accelerated, and the new mining area has less weight bearing down on it.

The solution was to establish a new production level about 200 meters – or 650 feet – above the existing DMLZ and slightly offset it. That way, the problematic harder to cave, lower grade rock that had hindered progress is bypassed. Production of easier to cave, higher grade ore is accelerated, and the new mining area has less weight bearing down on it.

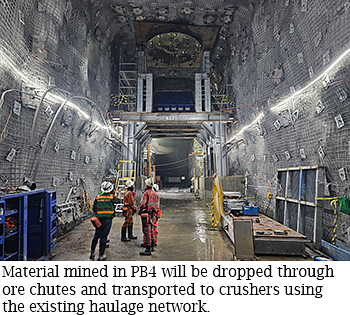

Since the new cave is an adjacent extension of the DMLZ, much of the equipment already in place for that operation can be used, including the existing two crushers and conveyors. Mined material will be carried by truck from PB4 and fed into long ore passes that will drop it down to the truck haulage level of the DMLZ for delivery into the crushers.

Improved conditions

The reconfigured cave is expected to be safer and help ensure production can be maintained, as the rich ore body is mined, said Matthew Sullivan, Senior Vice President, Underground Operations-PTFI.

In late January, the first blast, which initiated the caving sequence was fired in a ceremony attended by George Banini, Executive Vice President, Operations-PTFI, and Carl Tauran, Technical Mine Manager-PTFI.

Ignition of the explosives started the process of establishing a new cave at PB4 to gain access to the copper and gold in the mine. A video of that event can be viewed here.

“It’s the culmination of everybody on our team’s hard work,” Sullivan said. “It’s tens of thousands of hours of work, of everybody pulling together, then about three seconds of excitement, and it was over.”

The DMLZ is one of three operating underground mining zones at PTFI. Early indications of seismic instability were small, localized chunks of rock falling. Over time, the fractures in the rock grew larger, eventually causing heavy damage and requiring full tunnel closures.

The problem is the rock in the original path of DMLZ is too strong and rigid. Instead of breaking apart so it can be removed safely, the rock remains solid until it shatters under an extreme load. Sullivan likened it to scraping dirt from below a box of gravel versus a block of concrete. The gravel comes out easily and gradually. The concrete does not move until sufficient material is cleared away from underneath, then it comes crashing down all at once.

Permanent solution

For years, mining continued by using mitigation techniques like leaving larger support pillars spaced closer together. When it became clear the mine would need to be reconfigured, engineers from Freeport’s corporate office in Phoenix designed the alterations, working in close collaboration with counterparts in Indonesia.

For years, mining continued by using mitigation techniques like leaving larger support pillars spaced closer together. When it became clear the mine would need to be reconfigured, engineers from Freeport’s corporate office in Phoenix designed the alterations, working in close collaboration with counterparts in Indonesia.

One of the biggest challenges was the PB4 cave was designed and built while the balance of the DMLZ remained in operation, said Ian Edgar, Vice President, Underground Planning-Phoenix.

“We basically were mining up the ramp toward this new production level while continuing to produce from the existing lower level,” Edgar said. “We had to form a concept and go to avoid a production gap.”

When full production is reached in the next few years, the combined DMLZ is expected to produce about 40 million pounds of copper and 40,000 ounces of gold per month.