Integrating innovation and the new technologies of the future while being best at the basics today is Freeport’s way to Reinvent Mining, a comprehensive approach to mining that re-evaluates the old way of doing things to improve production, cut costs and ensure long-term competitiveness.

Integrating innovation and the new technologies of the future while being best at the basics today is Freeport’s way to Reinvent Mining, a comprehensive approach to mining that re-evaluates the old way of doing things to improve production, cut costs and ensure long-term competitiveness.

Reinvent Mining is more than just modernizing equipment or embracing recent technology, said Bert Odinet, Senior Vice President and Chief Innovation Officer. It is a new and dynamic way of thinking about how copper is produced from the shovel to the finished product to determine what is needed to make the entire process more efficient.

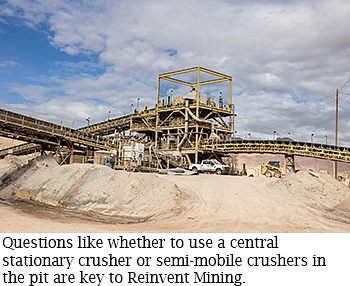

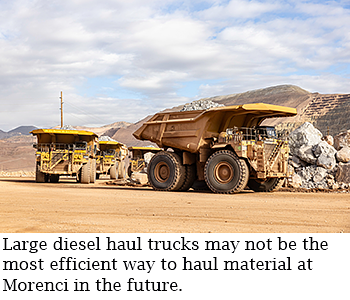

Rather than looking at a mining operation as individual functions – blasting, digging, hauling, milling, metal extraction, transporting – it analyzes the entire process from start to finish and identifies the best approaches to maximize value. That might be by using more efficient or cost-effective ways to move ore from the shovel to its destination. It might be developing new ways to extract the copper, as is being done through Freeport’s Leach to the Last Drop work. Or it might be through the better use of technology or data.

Emphasizing the basics

It all starts with being best at the basics of production today so maximum benefits can be attained by advances in the future, Odinet said.

“Reinvention is appropriate because it takes a bunch of innovations that have evolved over time in both process and technology, which weren’t available to us when we originally designed our operations, and thoughtfully applies them to our current state to enable greater efficiency,” Odinet said. “Right along with our critical Back to Basics work, we are going to be applying technology to drive efficiencies and rethink how the organization leverages the ore bodies and the assets that we have to mine more effectively into the future.”

Reinvent Mining to lower production costs is so critical to the company’s future that it has been added as a fifth pillar to the 2025 Strategic Objectives to help safely achieve production goals in the Americas. Other themes focus more on the immediate: Execute for Value, Leach to the Last Drop, Maintenance and Reliability, and Employee Experience.

Reinvent Mining to lower production costs is so critical to the company’s future that it has been added as a fifth pillar to the 2025 Strategic Objectives to help safely achieve production goals in the Americas. Other themes focus more on the immediate: Execute for Value, Leach to the Last Drop, Maintenance and Reliability, and Employee Experience.

Focusing on long-term sustainability

Reinvent Mining focuses on keeping the company strong long into the future by recognizing, planning for and embracing new opportunities to drive costs down. With mines in North America facing inflationary costs, longer haul runs and declining ore grades, it is imperative to develop ways to produce more copper at less cost.

The goal of Reinvent Mining is to achieve a production cost reduction of 10 cents per pound in Morenci – where the ideas will be tested – by the end of the first quarter this year. An additional 15 cents per pound of cost savings is anticipated by the end of 2025. The current aspiration is to add another 50 cents per pound of opportunities by the end of 2026 through the reinvented mining processes. Long term, the goal is to use process integration, innovations like Leach to the Last Drop and new technology to cut copper production costs in half.

Maximizing efficiency with technology

Reinvent Mining includes examining how integrating existing technologies across the production cycle can improve overall efficiency rather than looking at each step of the operation in isolation.

Reinvent Mining includes examining how integrating existing technologies across the production cycle can improve overall efficiency rather than looking at each step of the operation in isolation.

For instance, there are sensors that can be attached to shovels or conveyors that analyze each scoop of ore for its copper content and other minerals. However, if there is no way to sort the ore, that information is largely useless. The sensors become a nuisance and maintenance liability.

But, if the ore distribution system could be reconfigured in a way that allows more precise front-end sorting of ore grades so they can be processed in the most-cost efficient manner, the sensors become the vital first step in the chain.

For the short term, technology maturation teams are assessing what technologies are available now and which emerging technologies are worth investing in and preparing for, Odinet said. They also are planning ways to use that technology at scale in a large mine like Morenci.

“If we are going to be competing into the next century, we need to be really focused on how we apply these innovations and these technologies,” he said. “Especially in understanding what’s happening in our ore bodies, because as grades decline and as hauls increase, we are going to be challenged with cost issues if we aren’t doing things better and smarter.”