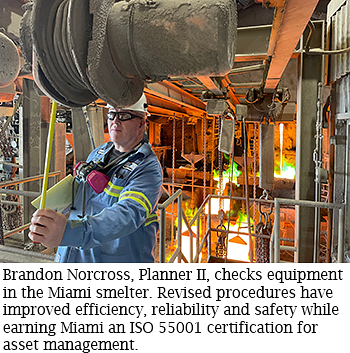

Two years of revamping equipment operation and maintenance procedures to improve reliability and efficiency have paid off for the Miami smelter, which recently achieved asset management systems certification from the International Organization for Standardization.

The Miami smelter complex, which includes such equipment as furnaces, an acid plant and anode casting facilities, recently was awarded the ISO 55001 certification. This certification is an industry standard for ensuring organizations effectively manage the lifecycles of their assets from design through disposal.

The Miami smelter complex, which includes such equipment as furnaces, an acid plant and anode casting facilities, recently was awarded the ISO 55001 certification. This certification is an industry standard for ensuring organizations effectively manage the lifecycles of their assets from design through disposal.

Getting it took a rigorous two-year process that involved changing how equipment is managed and maintained. The effort involved every level of the organization, from Mark Albertsen, General Manager-Miami, to front-line equipment operators and maintenance workers.

ISO is an independent nongovernmental organization that relies on experts to develop best practice standards for a variety of business functions.

For the Miami smelter, the application process alone took about a year and required multiple independent audits to ensure compliance with the rigorous ISO standards for asset management, said Raymond Tarango, Manager, Maintenance and Reliability, Power Controls-Miami, who was part of the team involved in meeting the requirements.

Incorporating ISO standards

About two years ago, a consultant was brought in to help align the processes in Miami to ISO standards.

The starting point was to integrate those standards with the 2024 strategic themes of the Americas to drive improved equipment reliability through maintenance and execution to achieve greater asset efficiency.

“It gave us the horsepower to get this done and getting it done in a pretty timely fashion,” Tarango said of the organization’s maintenance and reliability focus. “The consultant guided us on what the ISO standards were, and then we made it our own. We determined how to fit within the ISO standard and the corporate reliability processes and accomplish what we need to do at Miami for it to be successful. Then we developed those processes along the way internally.”

From the beginning, front-line workers from both operations and maintenance were brought into discussions about why attaining ISO certification was important. Meeting ISO standards would make the assets at the smelter more reliable and thereby improve efficiency. That would result in fewer unplanned repairs and longer equipment life.

From the beginning, front-line workers from both operations and maintenance were brought into discussions about why attaining ISO certification was important. Meeting ISO standards would make the assets at the smelter more reliable and thereby improve efficiency. That would result in fewer unplanned repairs and longer equipment life.

Tangible benefits to front-line workers include fewer late-night callouts for emergency repairs, better bonus potential based on higher production and improved safety because the equipment is operating properly.

“The key to success was that the smelter leadership team was onboard and committed to achieving ISO 55001 certification from day one,” said Larry Giannotti, Manager, Smelter Maintenance Services-Miami. “They made sure their teams were trained and knew the benefits of rolling these new processes out. The other necessary component was that Mark Albertsen was actively involved, provided support and all the resources we needed.”