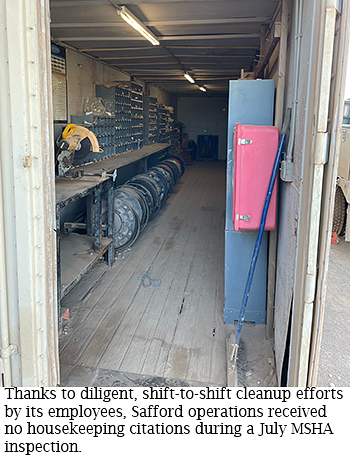

Safford operations recently underwent its second Mine Safety and Health Administration inspection for 2024, and the findings underscore how a commitment to being Best at the Basics can yield real results.

Safford recorded one of its most positive inspections in years, receiving zero housekeeping citations after MSHA closely examined its mine area, mine equipment and fixed plants. The site is one of only three in North America to have an inspection without a housekeeping citation so far this year, joining Chino and Henderson.

Meanwhile, Cerro Verde – while not governed by MSHA regulations in Peru – has reported similarly positive inspection results at its site.

Meanwhile, Cerro Verde – while not governed by MSHA regulations in Peru – has reported similarly positive inspection results at its site.

The achievement at Safford was particularly gratifying to that site’s Crush and Convey team, for whom housekeeping is an ongoing challenge.

Crush and Convey employees continuously monitor several miles and levels of crushing, conveyance and stacking facilities, all of which frequently shed loose ore material as it is moved from the crusher complex to the leach pad. Employees don’t make the mess, but they are responsible for cleaning it up, and the MSHA inspection affirmed they have been doing that well.

A recipe for success

“There’s always something that needs to be addressed, but safe access is one of the biggest areas of focus by MSHA inspections,” said Tony Battista, Superintendent Operations-Crush and Convey at Safford. “We do mock MSHA audits, and a team of leaders walks through our facilities every week looking for safety issues – from lighting to guarding to housekeeping.”

For Battista and other members of the Crush and Convey leadership, that regimen of safety walks, follow-ups and engineering controls – such as stacking unit “batwings” to redirect sloughing material – proved to be a recipe for success.

However, the employees committed to using those controls were the key ingredient in achieving this important milestone for Safford.

The achievement has raised the bar for ownership of safety across the site.

“Zero housekeeping citations certainly is a nice benchmark for Safford,” said Vicki Seppala, General Manager-Safford. “I’m proud that our employees make time to help ensure their workplace is safe, not just to avoid citations but because it’s the right thing to do.”

“Zero housekeeping citations certainly is a nice benchmark for Safford,” said Vicki Seppala, General Manager-Safford. “I’m proud that our employees make time to help ensure their workplace is safe, not just to avoid citations but because it’s the right thing to do.”

At Chino, that success can be attributed to the use of monthly safety topics and “No Fly Zone” meeting-free times that require site leadership to identify, resolve and report findings to the general manager. At Henderson, supervisors coordinate with leadership daily on targeted cleanup initiatives to focus resources more effectively.

Focusing on the basics

Stacey Koon, Vice President-Safety, Health and Technical Training, agrees with that sentiment.

While some employees may view housekeeping citations as easy targets for inspectors, Koon sees how the problem can be indicative of larger issues.

“Taking the time to keep work areas organized and clean, the most basic of the basics, makes working safely just that much easier,” Koon said.

She went on to explain that these regulations exist for a reason, and bad housekeeping can lead to injuries and, in some cases, serious outcomes that change peoples’ lives permanently.

Housekeeping also can impede the ability of employees to exit a work area quickly and safely in the event of an emergency. In August, the company experienced a PFE when a dozer hard nose fell during maintenance. While several controls were missing, poor housekeeping created tripping hazards when workers tried to avoid the falling hard nose. During the incident, one worker was injured.

“We talk a lot of being best at the basics, but it isn’t just a catchy slogan,” Koon said. “When it comes to safety, it’s ensuring we’re building on the strong foundation needed to keep everyone out of harm’s way.”