Imagine traveling far from your resources to perform a task and then realizing you’re missing a critical tool, part or other item for the job. Safford operations’ MIS team knows that pain all too well, but a new field shop provides the remedy.

Terry Knight, Superintendent, MIS-Safford, spent the last few years amassing the team and infrastructure needed to service the mine’s daunting galaxy of technology. A new Mine Technology Group field station is one of the most anticipated deliverables in that effort.

Terry Knight, Superintendent, MIS-Safford, spent the last few years amassing the team and infrastructure needed to service the mine’s daunting galaxy of technology. A new Mine Technology Group field station is one of the most anticipated deliverables in that effort.

"It’s closer to the action, so it’s convenient for the haul trucks and other vehicles we work on out on site,” Knight said. “The MIS office is too far away and inaccessible for those big rigs, so the new shop solves that problem.”

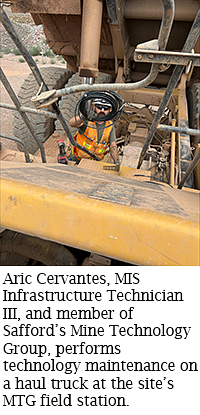

Safford's mobile equipment fleet – including nearly 60 haul trucks – oozes high-tech. Besides radios, there are GPS trackers, dispatch data systems and other networked gadgets that monitor things like machine health, tire conditions and operator alertness.

Time is money

Before the MTG station arrived, technicians ventured miles from their cache of resources at the MIS office to install or service those devices. They burned up a lot of time even before beginning the work.

“Servicing two trucks took up to two hours, including the drive from MIS, the tie-down, the work and the wait time (between trucks),” said Bobby Roberson, MIS Infrastructure Technician I-Safford. “Now, working from the MTG shop and coordinating with dispatch and Logistics, we can turn around two trucks – from problem to fix – in under 40 minutes.”

“Servicing two trucks took up to two hours, including the drive from MIS, the tie-down, the work and the wait time (between trucks),” said Bobby Roberson, MIS Infrastructure Technician I-Safford. “Now, working from the MTG shop and coordinating with dispatch and Logistics, we can turn around two trucks – from problem to fix – in under 40 minutes.”

Integrating MTG technicians with mine operations is another change helping increase technology service efficiency.

“As MIS employees assigned to Crews 1 and 2 in the mine group, we’re part of their team,” Roberson said. “Dispatchers can put trucks needing technology service on crusher runs right by our shop, so our wait time is, at most, 20 minutes.”

A practical solution

Having MTG technicians and service resources now stationed inside the equipment operation zone offers other benefits besides reduced vehicle downtime.

“Equipment that is down for tech issues won’t need to be parked at the truck shop anymore, leaving that space available for mechanical repairs,” said Bret Hunt, Manager Mine-Safford. “The MTG shop is more practical for getting truck tech issues diagnosed and addressed.”

A lot of time and planning went into the new facility.

“With input from the MTG team, we collaborated with the Projects team to get two new Conexes,” Knight said of the large cargo containers. “Those and another Conex already on site link together to create a shop with lighting, utilities, climate control, indoor storage, workspace and network connectivity."

“With input from the MTG team, we collaborated with the Projects team to get two new Conexes,” Knight said of the large cargo containers. “Those and another Conex already on site link together to create a shop with lighting, utilities, climate control, indoor storage, workspace and network connectivity."

The station’s easy access from Safford’s truck shop enables technicians to expedite follow-up work on vehicles freshly released from maintenance. The facility also is handy for installing tech components on new equipment before it’s put into service. Plus, the technicians can move the big machines as needed.

“We’re trained and green-carded to drive rigs like haul trucks, loaders and dozers,” Roberson said. “We can move equipment from the truck shop to the MTG station and then drive it to test technology functions. That way, we can catch and fix any problems before we release the vehicles to operations.”