If there’s been one prevailing sentiment for the maintenance team at the Chino concentrator, it’s this: One good turn deserves another.

If there’s been one prevailing sentiment for the maintenance team at the Chino concentrator, it’s this: One good turn deserves another.

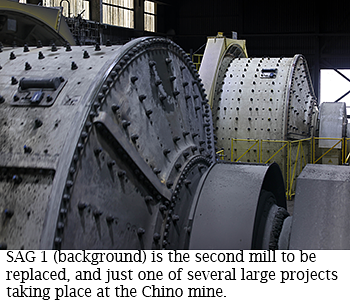

After last year’s replacement of the first of two new semi-autogenous grinding mills, or SAG mills, the new equipment shouldered the burden of production as the team began work on the second replacement—an undertaking it completed at the end of July.

While last year’s SAG mill replacement faced multiple setbacks and changes in scope, the second was completed on-schedule and in a month’s less time than the first, benefitting from lessons learned.

It is not often that people get the chance to do things over, said Sean Maddock, Mill Maintenance Superintendent-Chino. However, the lifecycle replacement of two mills so close together afforded the maintenance team a unique opportunity that they did not let pass.

“After the first SAG, we captured the issues and assigned them to leadership to ensure they didn’t reoccur,” Maddock said. “That willingness to recognize and learn from our mistakes was key to this project’s success.”

One change involved the team pushing back the project’s start date and completing as much pre-work as it could before taking the old SAG mill offline, reducing overall downtime.

One change involved the team pushing back the project’s start date and completing as much pre-work as it could before taking the old SAG mill offline, reducing overall downtime.

As an example of the safeguards, team members discussed how their improved understanding of hydro-demolition – a process used for the first time during last year’s SAG replacement – allowed them to better prepare for it. This included having adequate guarding and additional water sources already in place.

Ready for any contingency

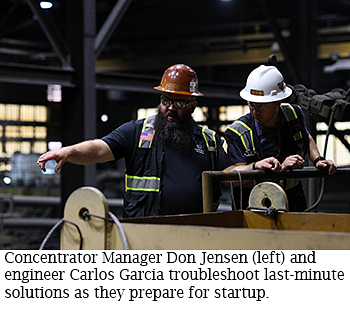

Even with all those precautions, some issues still arose.

The team faced a major challenge when the delivery of concrete did not meet specification, necessitating its removal and repouring, threatening the project’s timeline. The replacement also was supposed to synchronize with projects at the site’s filter plant, including new concentrate tanks with increased automation and an upgraded metal recovery unit. Delays there could impact the site's ability to more efficiently recover copper as it transitions back to a two-line run, operating both new SAG mills simultaneously.

Now that both SAG mills have been replaced, the goal is to not only employ that two-line run, but also raise the plant’s asset efficiency – a goal that will need to be balanced with Chino’s mine plan.

Now that both SAG mills have been replaced, the goal is to not only employ that two-line run, but also raise the plant’s asset efficiency – a goal that will need to be balanced with Chino’s mine plan.

Chino is no stranger to juggling multiple and sometimes competing priorities, with major projects taking place at the site's concentrator and hydromet operations in recent years. Though the SAG replacements are a once-in-a-lifetime event for many, there still are lessons that can be applied to ongoing and future projects to help those pieces better fall into place.

According to David Brence, Projects Engineering Manager-New Mexico Operations, this project shows the importance of consistent quality control and the timely completion of opportunity work – the additional maintenance or improvements that can be done during downtime – and the benefits of strong communications and cooperation.

“This wasn’t just a victory for the Engineering Department,” Brence said. “This was a concerted effort by everyone at site, at corporate and across the company to help make sure we completed on-schedule and without incident.”