Innovation, teamwork and coordination are essential to achieving the full potential of Leach to the Last Drop and producing 800 million pounds of new copper annually in the coming years, company leaders said during a recent two-day leaching summit for employees in Phoenix.

Innovation, teamwork and coordination are essential to achieving the full potential of Leach to the Last Drop and producing 800 million pounds of new copper annually in the coming years, company leaders said during a recent two-day leaching summit for employees in Phoenix.

The new techniques for extracting copper from existing stockpiles produced 144 million pounds that otherwise would have gone unrecovered last year and achieved a sustainable annual production rate of 200 million pounds.

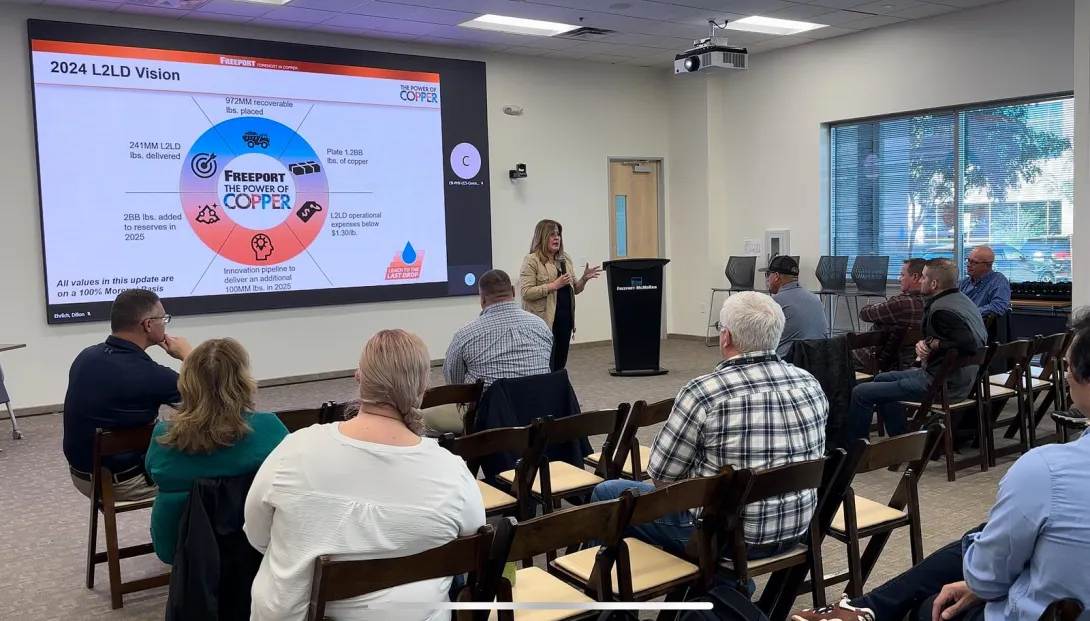

The expectation is that by building on previous success and bringing other innovations online, Leach to the Last Drop will produce at least 241 million pounds of copper this year.

“You guys are killing it,” said Kathleen Quirk, President. “You are getting more out of what we already have, and that’s the future of our industry. We are getting value out of copper that we never would have dreamed of getting.”

The 200 million pounds of copper being generated from Leach to the Last Drop is the equivalent of opening a new mine without the associated billions in expenses, several speakers noted. The cost of recovering copper is about $1.30 per pound.

“It’s the highest-value project in our portfolio,” Quirk said, adding she is the project’s “biggest cheerleader.”

Success, aspirations addressed

The conference brought together about 130 employees from nine mine sites across the Americas and the Technology Center. The two days of discussions covered the past successes and innovations being developed that will make Leach to the Last Drop an even bigger producer of low-cost copper in the future.

The conference brought together about 130 employees from nine mine sites across the Americas and the Technology Center. The two days of discussions covered the past successes and innovations being developed that will make Leach to the Last Drop an even bigger producer of low-cost copper in the future.

The new approach to leaching started as “a bit of daydreaming” a few years ago to find cost-effective techniques to tap the unrecovered copper in existing stockpiles, estimated at the time to be about 38 billion pounds and growing with each new load of ore, said Josh Olmsted, President and Chief Operating Officer-Americas.

It was a new way of thinking, Olmsted said during the conference at the Hub in Phoenix. Rather than starting with “why we can’t,” the mantra became “how can we?”

Collaboration was essential in developing new ways to extract copper from old assets, Olmsted said. The project was not confined to leaching and hydromet, but also involved people from other specialties such as operations, mine planning, data analytics and global supply chain.

Olmsted said it is important to maintain that spirit of collaboration between sites and departments. Every employee has a stake in Leach to the Last Drop’s success as it becomes an ever-bigger part of the company’s production, he said.

Olmsted said it is important to maintain that spirit of collaboration between sites and departments. Every employee has a stake in Leach to the Last Drop’s success as it becomes an ever-bigger part of the company’s production, he said.

“Be the example,” he said. If another site or department needs help, offer it. If you need help, ask for and accept it.

“We are all in this together,” Olmsted told the attendees. “If we can demonstrate the innovation, demonstrate the creativity and the willingness to think differently and attack problems and show results, I think it just starts to catch fire and a lot more people start to think differently about the way they work.”

Key contributors recognized

A number of employees who have helped make the Leach to the Last Drop effort a success were recognized with awards presented throughout the conference.

- Collaboration – Ashlyn Thille, Senior Metallurgist, Intellectual Property-Tucson Technology Center, and Othon Palma, Business Intelligence Analyst I-Morenci

- Innovation – Sarah Lyons, Senior Metallurgist-Tucson Technology Center

- Leadership – Raquel Crossman, Chief Metallurgist-Tucson Technology Center,

- Team Award – Project Root (Recovery Optimization & Operational Team)

- Stay The Course Team Award – Bobby Holder, Senior Supervisor, Materials Distribution-Morenci

- Lifetime Achievement – Lex Zerwas, Contractor Consultant-Finance (formerly Director, Operations Strategy and Controller), and Larry Todd, Contractor Consultant (formerly Manager, Processing Operational Improvement)

- Front Line – Hector Romo, Hydromet Leach Operator II-Morenci