Anyone who has ever under-watered a house plant to its demise should understand why metallurgists like Pip Killian are so pleased about the prospects of turning parched portions of leach piles into late-blooming copper producers.

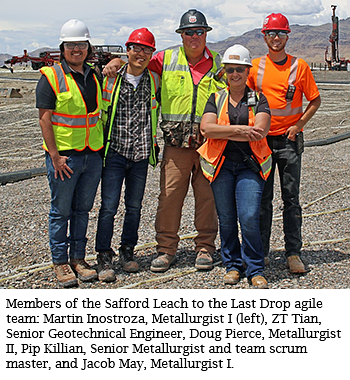

Deep raffinate injection – sending raffinate solution down holes drilled into the leach pad at various lengths – is how Killian, Senior Metallurgist-Safford, and her agile team are getting at 94 million pounds of recoverable copper in a pie-shaped portion of the Safford pad known as the “Wedge.”

“It’s an area where the two pads overlap, a prismatic shape that runs the length of the pad, and we're drilling into because we know it's not been leached very well,” Killian said.

Using instrumentation and data analytics provided by the geotechnical team, company metallurgists now can identify areas not relinquishing copper because they are not receiving sufficient raffinate. Metallurgists also can map ponds and seeps where raffinate is ponding rather than dispersing.

Employees performing key work

Safford metallurgists knew it would be economical to go after the copper in the Wedge, provided the work was done in-house.

Safford metallurgists knew it would be economical to go after the copper in the Wedge, provided the work was done in-house.

“I knew a lot would depend on being able to do the drilling ourselves rather than contracting it out,” said Rosa Payne, Chief Metallurgist-Safford. “This wedge has 270 holes, so we’re not going to finish for a long time, but we’re anticipating that our grade will be sufficient for the payoff to be fast, like within a few months.”

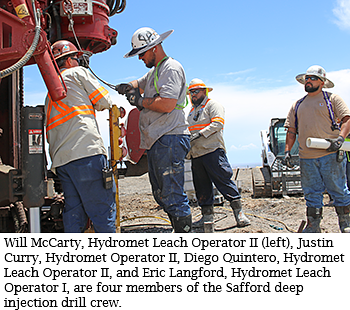

As employees on the four-person drill crews at Safford and Miami will attest, there’s a lot more to deep raff injection than just drilling a hole.

“With each hole, you have the steel casing. Then you put in the little, three-inch pipe to deliver the raffinate, then you put gravel around it, and then finally, you pull the drill steel out,” said Sara Viau. Metallurgist II-Miami. “Our guys developed a good skill set at doing this, so Safford borrowed the crew and the drill to help them through July.”

Drilled holes provide potential

All that hard work drilling those hundreds of holes could deliver an additional payoff, this one not from injection but rather its opposite – extraction. By targeting areas where pregnant leach solution – the raffinate that has collected copper during the process – is ponding, metallurgists can use similar holes as pump-back wells to suck up the pregnant leach solution like a straw.

“I'm almost more excited about pumping solution out, because we know that we have saturated layers with solution that is likely higher grade than what we’re leaching from the surface,” Payne said.

Viau said she really likes the way deep raff injection synergizes so well with the other Leach to the Last Drop initiatives.

Viau said she really likes the way deep raff injection synergizes so well with the other Leach to the Last Drop initiatives.

“Once you have a well field on a stockpile, if you want to heat solution directly, it’s a lot easier to target buried sulfide ore first if we’re heating one / two well lines above the sulfides instead of the entire stockpile. Likewise with additives and air injection you might want to use,” Viau said.

Raffinate injection is something of a rescue operation for at-risk copper, Killian noted.

“We're using different technology to be able to more effectively leach that copper that might be at risk, copper that we may or may not get because it's deep within the stockpile and becomes harder to leach as the stockpile gets older and less permeable,” she said.