Freeport-McMoRan’s Technology Center Tucson quietly made history last year when North American solvent extraction and electrowinning tankhouses replaced a synthetic chemical with a proprietary mist suppressant as environmentally safe as all-natural candy because it actually is all-natural candy.

Technology Center researchers landed on one of three strains of the licorice plant as the jackpot they’d been looking for after studying and testing hundreds of ways to tame the bubbles that naturally pop off electrowinning solution in tankhouses like the soda bubbles misting off a freshly poured fountain drink.

Technology Center researchers landed on one of three strains of the licorice plant as the jackpot they’d been looking for after studying and testing hundreds of ways to tame the bubbles that naturally pop off electrowinning solution in tankhouses like the soda bubbles misting off a freshly poured fountain drink.

“It was once thought to be impossible to replace the chemical we used at elevated electrowinning current density in tankhouses,” said Scot Sandoval, Manager, Metallurgical Research-Technology Center Tucson. “Three years of hard work brought this about, from lab-scale to pilot-scale to full commercial-scale.”

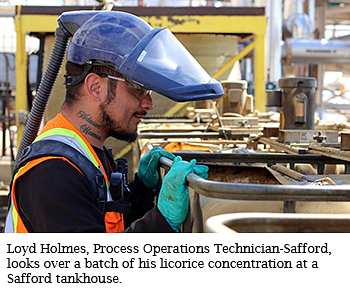

Since the licorice rollout, frontline employees like Loyd Holmes, Process Operations Technician-Safford, have done the work of dialing in just the right concentration of licorice and feeding it into the electrolyte solutions in the tankhouse.

Persistence pays

It was through Holmes’ persistence, brainstorming and experimenting that Safford realized the right dose, temperature and dosing sequence that unlocked licorice’s mist-suppressing power.

“When I could induce that foam, that small amount of foam on the surface of the solution, that’s when it would work great,” Holmes said. “It was finding the right dilution and the right temperature, and then just figuring out a way to feed it.”

From the original licorice concentration sold by the vendor, Holmes gradually kept experimenting and diluting the solution down to an ideal concentration level. He also found heating the water better helps dissolve the licorice powder mixed in totes that are then pumped into the electrolyte solution. Holmes even found unused parts in a salvage yard that could be fashioned into a pumping system to deliver a constant feed to the tankhouse.

From the original licorice concentration sold by the vendor, Holmes gradually kept experimenting and diluting the solution down to an ideal concentration level. He also found heating the water better helps dissolve the licorice powder mixed in totes that are then pumped into the electrolyte solution. Holmes even found unused parts in a salvage yard that could be fashioned into a pumping system to deliver a constant feed to the tankhouse.

“We weren’t budgeted for new equipment during the pandemic, so Loyd had found this old tank in a laydown yard, and he had some guys help drag it up to the tankhouse,” said Ryan Magnuson, Senior Metallurgist-Safford. “He took a photo of it set up there and wrote ‘Come on guys. It’s right here. Let’s do this!’”

Licorice use widespread

Pilots of the licorice suppressant at both Safford and Miami operations have convinced leadership to implement its use at all company tankhouses. The company’s proprietary solution, for which it is securing a patent, is made of licorice, water and another ingredient that acts as a binder.

“The patent application is really about just ensuring that we can continue to use the product for our employees,” said Ephrem Gebrehiwot, Senior Metallurgist-Technology Center, who, among other projects, has been working on finding a safer mist suppressant for a dozen years.

“At one time, this goal was seen as unachievable,” Gebrehiwot said. “The company has been working on this for 20 years, and we tried hundreds of chemicals. To be able to identify and develop this solution and take it from the research to pilot stage to commercial is an achievement we should be proud of.

“To me, it shows that we are keeping our promise as a company to always look for better ways to do things for our employees and use the most environmentally friendly materials we can.”