Sierrita is leveraging lessons learned from an improvement project more than 250 miles away at Bagdad.

Sierrita is leveraging lessons learned from an improvement project more than 250 miles away at Bagdad.

In 2018, Bagdad optimized its mill with instrumentation, computing power and better ways for employees to collaborate, reaping gains so impressive they’ve since been adopted companywide, and now Sierrita is doing the same with crushing.

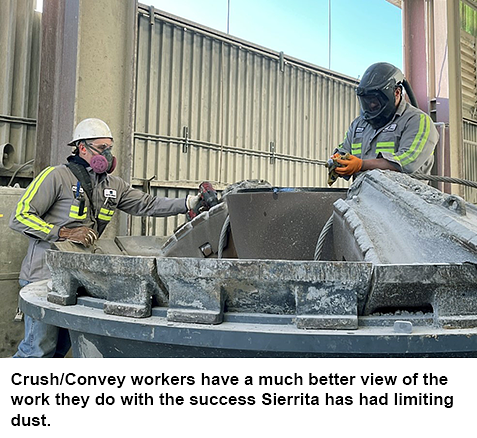

The comprehensive plan to mitigate dust and minimize crusher downtime started around the time the pandemic-prompted shutdown was easing up, and it was developed and implemented in-house with a contractor’s assistance. It features an operating matrix that captures the qualities of a best day of operations followed by measuring, benchmarking and favorably tweaking those qualities. The effort has yielded results readily seen in metrics, not to mention results literally seen as opposed to obscured by a perpetual cloud of crusher dust.

“We came up with an operating matrix for our operations to be able to track the throughputs of what was happening with every piece of equipment, and that got us standards of what we should be seeing if everything is running correctly,” said Procopio Gonzales, Sierrita Mill Superintendent.

The operating matrix is similar to the company’s remote asset monitoring process (RAMP) that uses data culled through remote sensing to improve haul truck availability and driver performance through the Haul Truck Operator Scorecard.

Upping efficiency means the mills that grind what the crushers crush yield more copper from the ore at a faster milling rate, a tandem known in mining lingo as “recovery and throughput.”

On a best day you can see forever… or at least a lot better

Though it also spawned the efficiency gains associated with better housekeeping, the project’s biggest payoff comes in the form of improved working conditions for crusher employees.

Though it also spawned the efficiency gains associated with better housekeeping, the project’s biggest payoff comes in the form of improved working conditions for crusher employees.

One of the solutions helping achieve that is the Guzzler, which looks like a blue garbage truck and acts like a giant central vacuum. The operator just drives it up to a fitting outside the building that connects to ductwork inside, and the Guzzler does its thing.

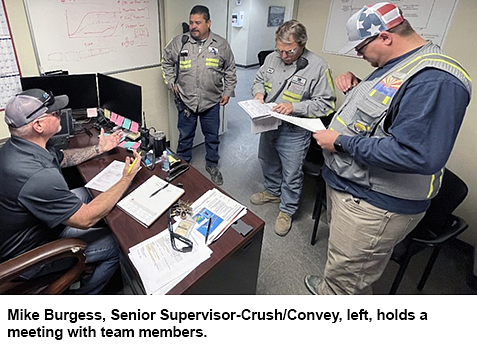

Another action item was the creation of a new, top-level position for crusher operators. Its creation directly connects to Develop and Coach, one of the five Freeport Edge behaviors, said Mike Burgess, Senior Supervisor-Crush/Convey.

“It’s an hourly position, but these employees are going to be learning the same things as supervisors in order to step across as supervisors, should they want to,” Burgess said. “And even if they don’t want to become a supervisor, they will still be able to provide valuable relief time or coverage when a supervisor is out.”