During a recent incident at the Canyon maintenance site, the crew's strong commitment to safety helped ensure no one was injured while replacing a belt, even when unexpected equipment failure occurred.

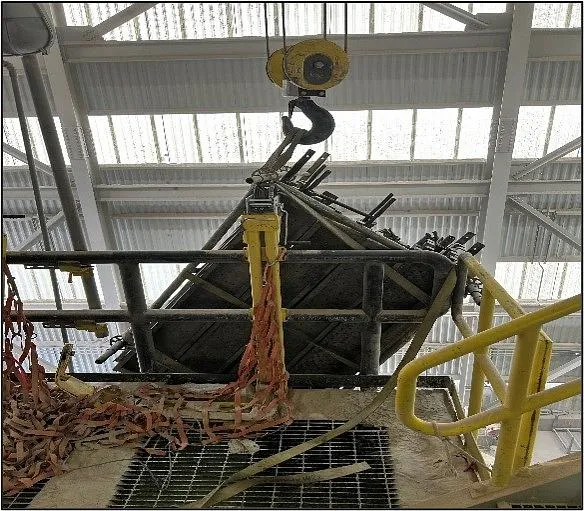

The belt replacement required the use of an overhead auxiliary crane to hoist two scaffold racks to the feeder floor for assembly. The first rack was successfully hoisted and landed on the feeder floor without incident. However, while hoisting the second rack, the crane's control box faulted, causing the operator to lose control of the crane functions. The load began descending on its own and became lodged against a handrail.

Despite this unexpected equipment malfunction, the crew's preparedness and adherence to safety protocols ensured that no one was injured. Before starting the work, a thorough tailgate meeting was conducted, and a Job Risk Assessment (JRA) was completed. All employees in the area were informed about the work and the necessary safety controls.

The use of flagging and spotters played a crucial role in keeping employees out of harm's way. This incident underscores the department's commitment to Fatal Risk Management, with both leadership and employees actively participating in maintaining a safe work environment.

Area supervision's dedication to employee safety is evident through their consistent implementation of good tailgates, JRAs and workplace exams. These practices are effective in creating a culture of safe production and preventing injuries.

This incident serves as a reminder of the importance of safety protocols and the positive impact of a proactive safety culture.